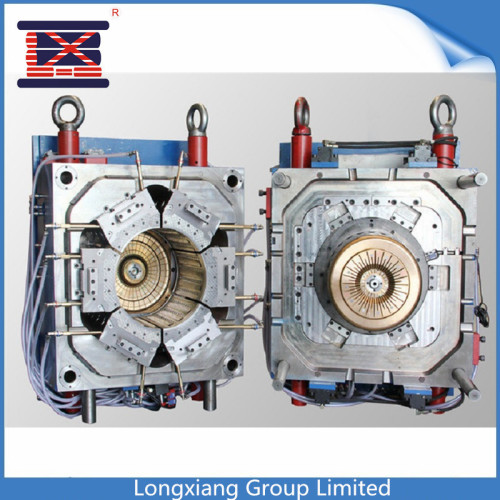

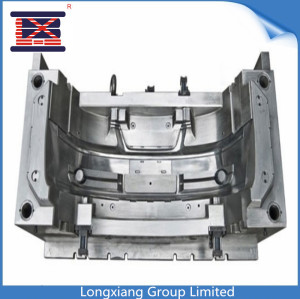

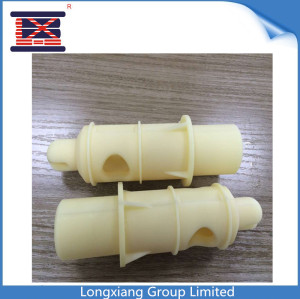

China Supplier Electronic Spare Parts Plastic Injection Mould

- Model

- LX0047

Item specifics

- Product Name

- over mold

- Mold Standard

- HASCO, DME, MISUMI, JIS, LKM, etc.

- Cavity

- Single or Multi cavities

- Mold Material

- 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, S50C etc .

- GateType

- Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc.

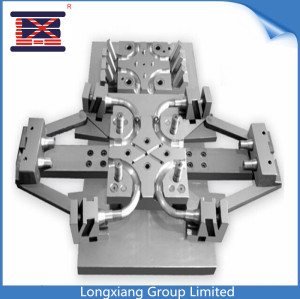

- Mold Tooling Equipment

- Lathe,Milling,Grinder,Drill,CNC,EDM, Wire cut machine,Punch machine

- Injection Mold Machine

- 80T-3000T

- Product Material

- ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc

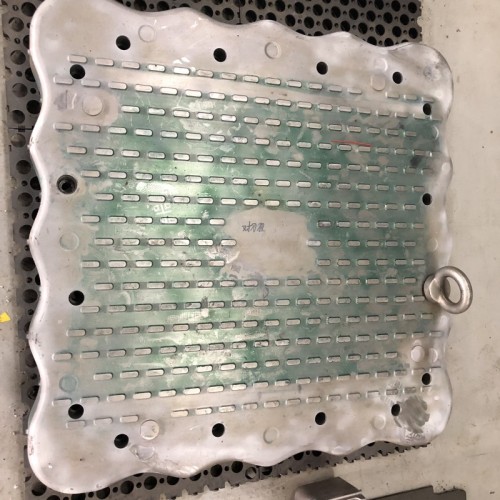

- Surface treatment

- Polish. Etched. Texture, Heat treatment and Nitriding

- Mold Life

- 45#:50,000 to 100,000 shots; P20:100,000 to 200,000 shots;718: 200,000 to 300,000 shots; H13: 300,000 to 500,000 shots

Review

Description

1. Grade: precision plastic injection mold parts

2. Size: Customized

3. Standard: Customized

4. Certification: ISO9001, CE

1.Sample/Drawing | We need your require clearly | |

↓ | ||

2.Negotiation | Material, cavity, price, delivery time, payment term, etc. | |

↓ | ||

3.Place order | According your own design or choice our design | |

↓ | ||

4.Mould design | We will communicate&Exchange the opinion with you during making drawing. | |

↓ | ||

5.Tooling mould | After customer approve the mould design will start making mould | |

↓ | ||

6.Mould process | Provide updated tooling schedule every week to show the process | |

↓ | ||

7.Sample confirm | Send you sample for conform it, if not satisfied by customer. We modify mould. | |

↓ | ||

8.Delivery mould | Delivery mould after customer approve sample and arrange shipment | |