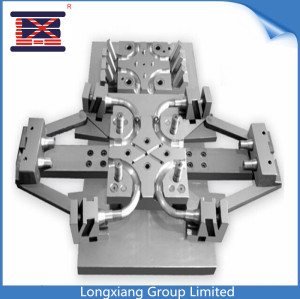

Widely Used Superior Quality Plastic Waste Dust Bin manufacturer

- Model

- LX-005

Item specifics

- Mold Material

- 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343,

- Product Material

- ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc

- Mold Standard

- HASCO, DME, MISUMI, JIS, LKM, etc.

- Injection Mold Machine

- 80T to 2800T

- Mold Tooling Equipment

- Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine

- GateType

- Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc.

- Runner Type

- Cold Runner or Hot Runner

- Cavity

- Single or Multi cavities

- Mold Life

- 5000-500,000 shots

- Lead Time

- About 30 days

Review

Description

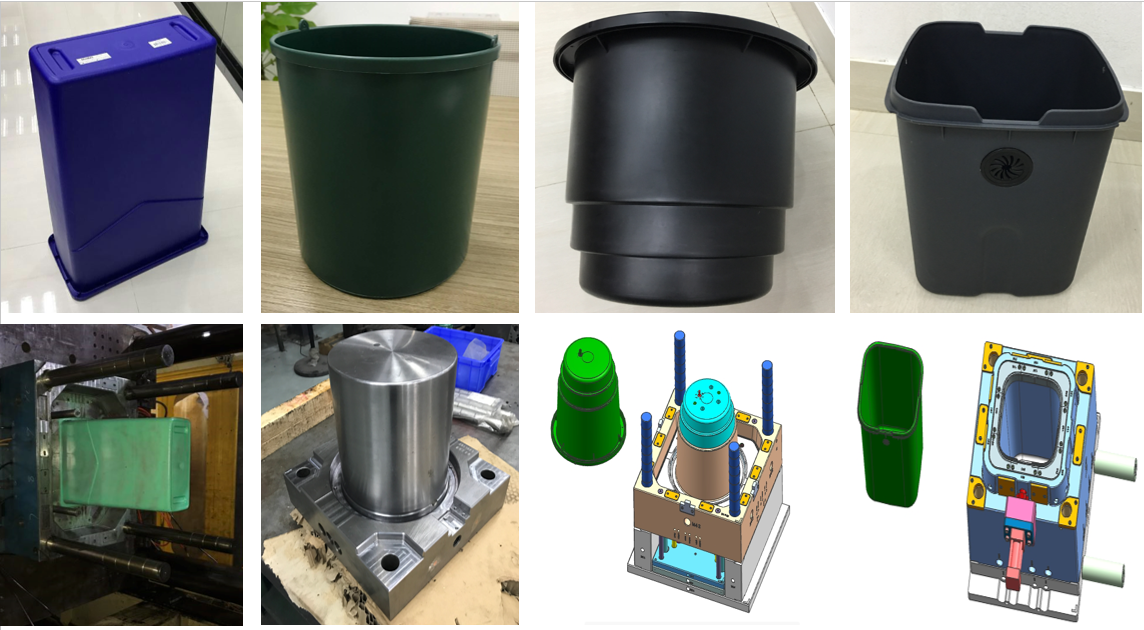

| Mold Material | 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

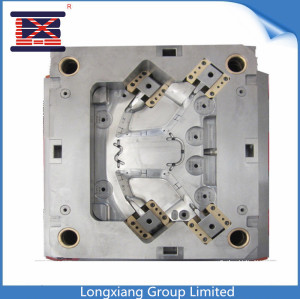

| Mold Type | Plastic Injection Molding |

| Product Material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc |

| Mold Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold Tooling Equipment | Lathe,Milling,Grinder,Drill,CNC,EDM, Wire cut machine,Punch machine |

| Injection Mold Machine | 80T to 2800T |

| Product Weight | 50-20000g |

| GateType | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Runner Type | Cold Runner or Hot Runner |

| Cavity | Single or Multi cavities |

| Treatment | Heat treatment and Nitriding,polish ect. |

| Mold Life | 45#:50,000 to 100,000 shots |

| P20:100,000 to 200,000 shots | |

| 718: 200,000 to 300,000 shots | |

| H13: 300,000 to 500,000 shots | |

| Lead Time | Generally mold making will take around 30 days 7-10 day to mass production |

| Package | Wooden packing box for molds inner packed in opp bags, outside packed in standard export carton |

1. Q: Which kind of product can you do?

A: Plastic injection molding and mass production for plastic parts.

2. Q: Which kind information need for quotation?

A: 1) Sample photo with size or 2D/3D design

2) Product material

3) The quantity

4) Runner type, cold or hot

5) Mould steel type, P20, 718, 2738, H13, S136, 2316, an so on.

3. Q: I have no 3D drawing, how should I start the new project?

A: You can supply us a sample or tell me your idea,we will help to finish the 3D drawing design.

4. Q: How long will be the injection mold finished?

A: Usually it will take about one month to finish the mold.

5. Q: How about the samples?

A: After mold finished, We will make some samples for you to check as soon as we finish the mold and then deliver the samples for you to check.

6. Q: How about the mould modify?

A: You can tell us your comment about the samples after you receive them.If there is any dimension different from the drawing,we will modify the mold for free in our side and then make the new samples.

7. Q: How about the proprietary rights of the plastic injection mold?

A: Customer paid the mould so it all belong to Customer.

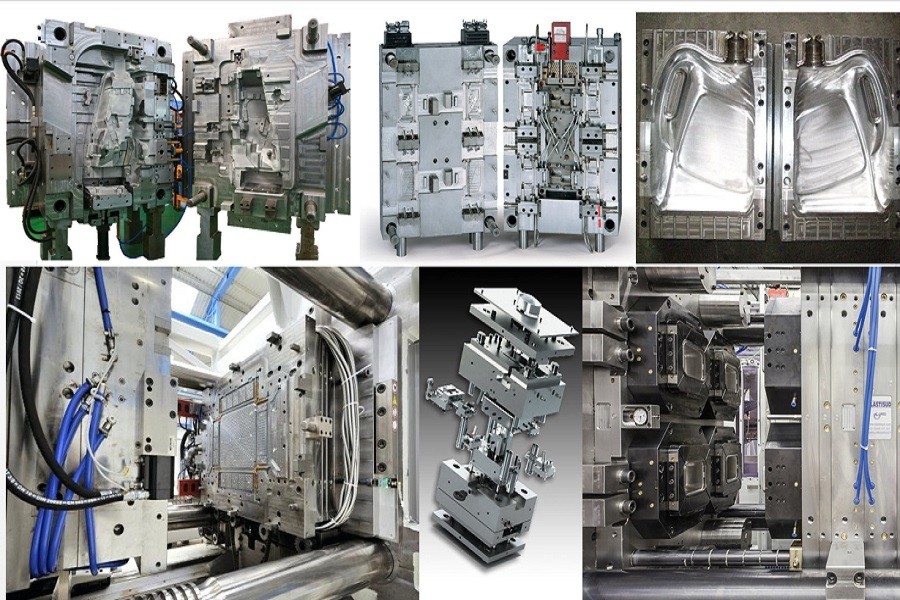

1. Manufacturing and exporting experience for over 20 years. ISO 9001 approved

2. Products are supplied to over 50 countries.

3. One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. 24 hours (two shifts) / 6 days for production.

8. Professional design team, mold maker engineer. OEM/ODM service.

9. Professional QC and R&D teams to assure high quality.

10. Professional sales team. Good English capabilities and communication skills.

11. No MOQ.

12. Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

13. Geographical advantages: within 30 minutes to airport or sea port, near to Hongkong.