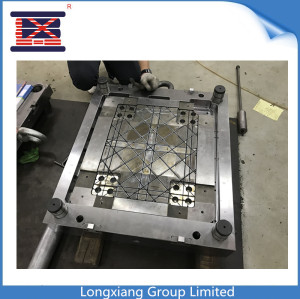

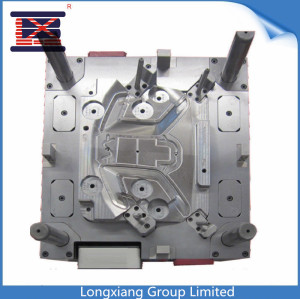

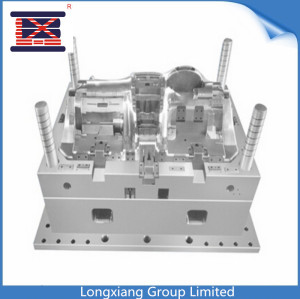

Longxiang FDA degree customized Plastic Injection Mould for food grade products

- Price

- US $4500

- Model

- LX0026

- MOQ

- 1 set

Item specifics

- Product Name

- plastic/silicon rubber mold

- Mold Standard

- HASCO, DME, MISUMI, JIS, LKM, etc.

- Cavity

- Single or Multi cavities

- Mold Material

- 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, S50C etc .

- GateType

- Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc.

- Mold Tooling Equipment

- Lathe,Milling,Grinder,Drill,CNC,EDM, Wire cut machine,Punch machine

- Injection Mold Machine

- 80T-3000T

- Product Material

- ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc

- Surface treatment

- Polish. Etched. Texture, Heat treatment and Nitriding

- Mold Life

- 45#:50,000 to 100,000 shots; P20:100,000 to 200,000 shots;718: 200,000 to 300,000 shots; H13: 300,000 to 500,000 shots

Review

Description

Basic Features

> Material: ABS,AS,PP,PPS,PC,PE,PEI,PES,POM,PMMA,PS,HDPE,TPE,TPU etc

>Manufacturing Method:Plastic Mould Injection

>Surface treatments: Polishing,Plating,Painting,Silkprinting

> Drawing formats: .STP;.IGS;.DXF;.DWG from Pro.E or Solidworks files

Mold Discription

| Mold Base | LKM, HASCO, DME or upon customer's requirement |

| Mould Cavity | Single/Multi 1*1,1+1,1*2,1+1+1,etc |

| Mold Material | P20,NAK80,SKD11,S316,S50C,S45C,718H,718 or customers' appointed |

| Mode Gate | Fan gate,Sub gate,Pin Point gate,Valve |

| Ejection system | Stripper plate,Lifter,Push Bar,Ejection Pin etc |

| Mold Runner | Hot/Cold runner available |

| Mold life | 500,000 shots - 2,000,000 shots |

| Packaging details | covering with film for anti rust and packed with wooden Case |

| Export Country | Janpan,Europe,USA,Mexico,Australia,Middle East,Asia etc |

Product Discription

| Type of plastic mold | 3-plate mold,2-plate mold |

| Product Material | ABS,AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

| Surface finish | Polishing,Painting,Slik print,Anodizing,Plating,etc |

| MOQ | not request |

| Lead time | 15-35days after deposit received |

| Packaging details | Carton box or wooden Case upon product weight and customer's requirements. |

| Shipping | By sea or by air as customer requirement |

| Export Country | Janpan,Europe,USA,Mexico,Australia,Middle East,Korea,Asia etc |

Following is also the essential informations, for customer reference

1.Ready step | customer suppy us 3d drawing or sample .we make the injection mould drawing |

| |

2.Negotiation | the quality, price, material, delivery time, payment item, |

| |

3.Place an order | according to the confirmed plastc injetion mould drawing |

| |

4. Mould | According to customers request to build the injection mould. Before make the mould, we send mould design to customer approval first, and cusotmer pay the deposit... before move forward to production; we will send samples to customer to confirm first. |

| |

5. Sample shoot | If the first sample come out is not satisfied customer, we will modify the mould till meet customers satisfactory. |

| |

6.Products in store | If your quantity is beyond our storage, we will provide lead time to you. |

| |

7. Delivery time | Delivery goods by sea or by air, according to customers requirement. |

Contact information:

Milan Chua

Email: sales4@longxiang-ltd.com||www.longxiang-ltd.com

Ph: 0086-13570392519||Skype: milan-longxiang

Tel: 0086-020-29869896||Fax: 0086-020-29869896

QQ: 3251825297||Wechat/whatsapp: 13570392519

Office Address: Room1806, NO.80 Jingang Road, Minjie International Building, Nansha, Guangzhou, GunagDong, China, 511400.

Factory Address: No.96-1 Qixin Road, Dongchong Town, Nansha District, Guangzhou, Guangdong, China, 511453.